J&B News & Updates

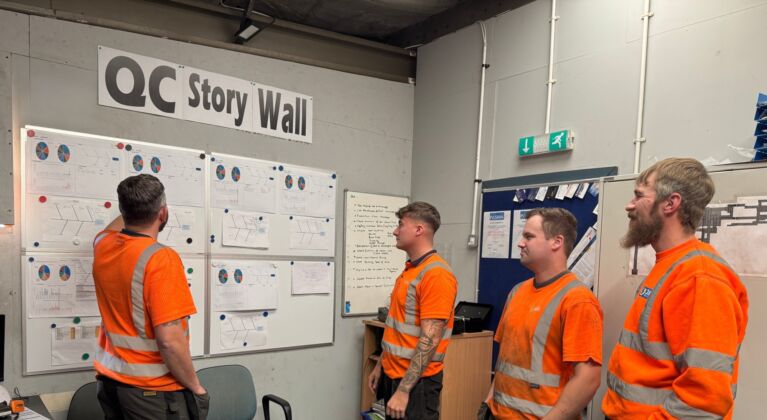

QC Story Wall at J&B Recycling

22.08.25

Our team work hard to keep our MRF running efficiently, so that we can offer the best service to our local community and clients. Our Maintenance Team play a huge role in making sure the plant is safe, reliable and ready to handle the daily demands of sorting processing and recycling.

To support that, the team has introduced QC Story Walls – a structured and simple way of working together to improve reliability and reduce downtime.

What is a QC Story Wall?

A QC Story Wall is a visual tool that helps the maintenance team focus on areas where extra attention can make the biggest difference. It starts with tracking where downtime occurs, then the team come together to discuss possible causes and agree on the most effective actions to take. This allows our team to contribute ideas and ensures that changes to the plant are made based on facts and data.

The process isn't designed to highlight problems, it is about identify areas of opportunity, so we can build on the already good work happening on the plant. Giving the team time and space to make things even better.

How has the Team responded?

Since introducing the QC wall, the maintenance team have been getting involved heavily to improve efficiency. At first, they were naturally quiet as they adjusted to a new way of working, but now they enjoy sharing ideas and contributing suggestions, even during night shifts. This shows that the Story Wall is helping to create a more collaborative environment, where everyone can be a part of the process.

Mark, one of our engineers said ""Its great that we can facilitate meeting as a team and focus on specific issues."

Real Improvements

This new system has already made a measurable difference. One early project focused on Belt 330, which was experiencing multiple resets every shift. By dedicating time to look closely at the data, understand the root cause, and agree actions as a team, the issue was eliminated. Simply creating space and structure for problem solving, solutions come quickly.

Moving Forward...

The QC Story Wall is doing more than just helping us fix specific issues, it’s changing the way the team works together. By sparking more open conversations, it helps everyone feel comfortable sharing ideas, and giving the whole crew some ownership over the improvements we make.

It’s also bringing different parts of the business together. Maintenance and Production are now collaborating more closely, working side by side to find the best solutions when a challenge needs both teams involved.

By working this way, we’re making sure the MRF keeps getting better – staying reliable, efficient, and ready to meet whatever’s next.

We would like to say a huge thanks to our engineers and maintenance team who keep operations running 24/7 on site! Thanks for all of your hard work.

Delivery & collection

services covering

the UK

Where we operate

Request a quote

For an instant quote, call our team on

01429 272810- 1. Waste type

- 2. Company Details

- 3. Enquiry Details

- 4. Thank you